WHC

WHC

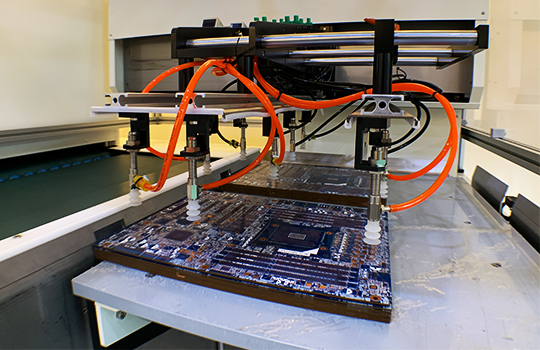

Improving production efficiency is one way to reduce production costs

Feature of Product

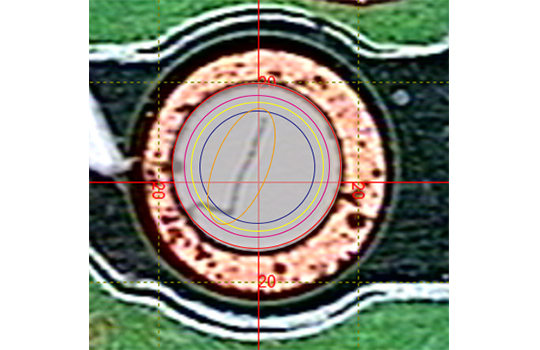

Automatic LED light source adjustment

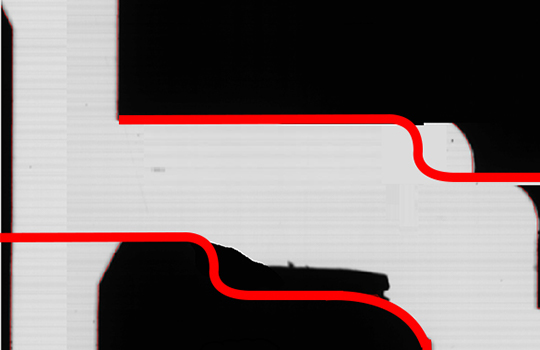

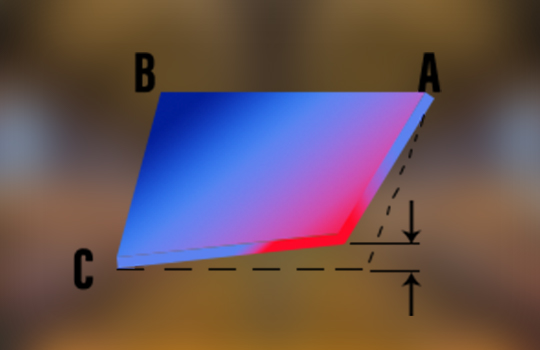

Molding inspection function

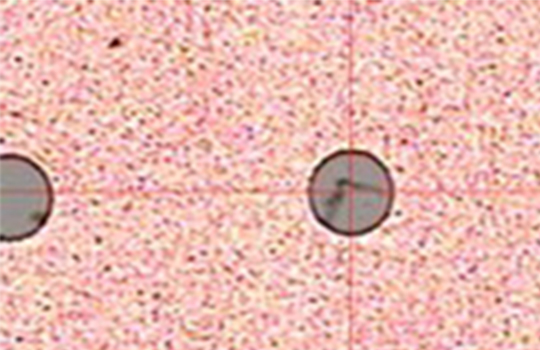

Super strong burr check

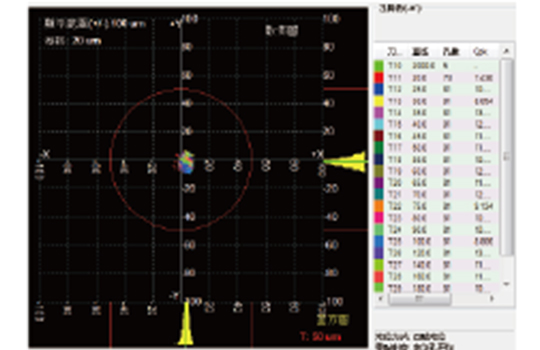

6-wire simultaneous detection

The WHC can not only perform fast hole inspection, but also develop a multi-line inspection function of up to six lines of simultaneous hole inspection. Breaking the previous inspection method of only single line or double line, the efficiency of hole inspection is further improved.

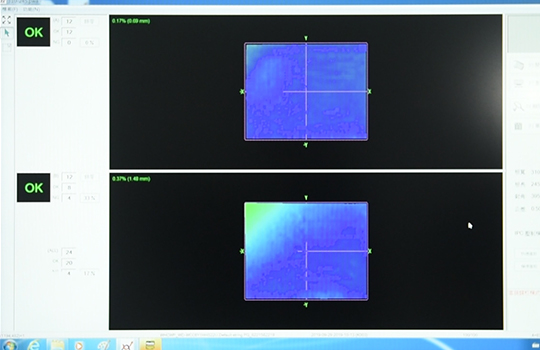

Unique automatic optical correction and specially designed LED light source control, after the relevant parameters are changed, the system will automatically correct to ensure the accuracy of each scan.

Integrating optics, electronics and software, Ventan uses its unique image recognition technology to improve the ability to detect debris, even small flaws can be stably detected. Beyond the optical depth of field, double-sided inspection as required.